Servos

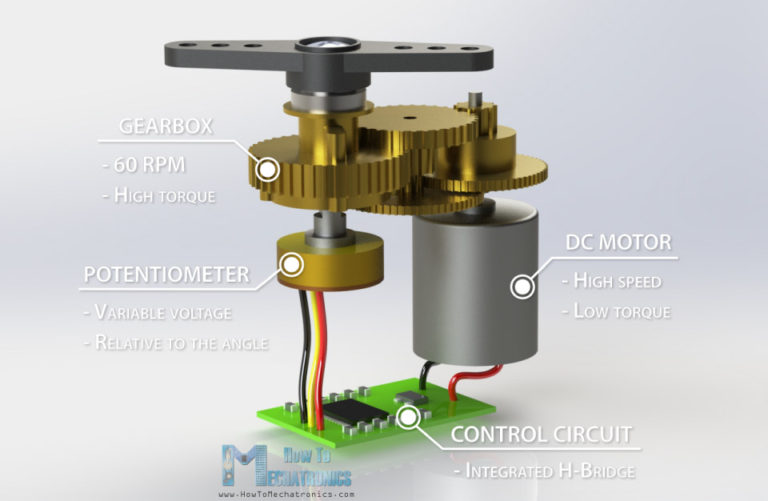

- Standard servos are used to maintain a certain angle, not meant for full rotation

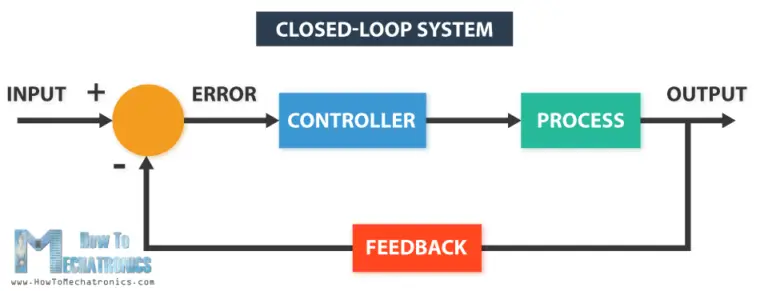

- Uses closed-loop feedback control

- Servos are used in applications requiring high torque, accurate rotation within a limited angle such as Robotic arms, valve control, rudder control etc.

SG90 Micro Servo

- SG90 is a servo motor which operates based on PWM control signals

- The servo maintains a certain angle (position) based on the width of the pulse fed in through a signal input

- Some technical specifications

- Weight: 9 g

- Dimension: 22.2 x 11.8 x 31 mm approx.

- Stall torque: 1.8 kgf·cm

- Operating speed: 0.1 s/60 degree

- Operating voltage: 4.8 V (~5V)

- PWM frequency = 50Hz

- Pin configuration: Yellow / Light Orange / White (Signal), Red / Dark Orange (+5V), Brown/Black (Ground)

Note : The pulse width in the image does not correspond to SG90, for illustration of the concept only.

Image courtesy: Stefan Tauner

544 – 1500 – 2400 us

0° – 90° – 180°

Continuous Rotation Servos

- Continuous rotation servos are normal servos modified to perform open loop speed control (instead of closed loop position control)

- Rotation speed and direction are controlled through PWM signals (pulse width) for continuous rotation servos, just like how position is controlled for standard servos

- Effectively, continuous servos are DC motors with integrated motor drivers and reduction gears in a compact, inexpensive package

- FS90R continuous rotation operating speed: 110RPM (4.8V); 130RPM (6V)

- Can continuous rotation servos be used to achieve accurate positioning without any additional hardware?

Servo Library

- This library allows an Arduino board to control servo motors.

- Standard servos allow the shaft to be positioned at various angles, usually between 0° and 180°. Continuous rotation servos allow the rotation of the shaft to be set to various speeds

- Any digital pin on UNO can be used, not necessarily those supporting PWM. However, note that using Servo library disables analogWrite() functionality on pins 9 and 10

- attach(int) - attach a servo to an I/O pin, e.g., servo.attach(pin), servo.attach(pin, min, max)

- servo: a variable of type Servo, pin: pin number, default values: min = 544 us, max = 2400 us

- write(int) - write a value to the servo to control its shaft accordingly

- Standard servo - set the angle of the shaft

- Continuous rotation servo - set the speed of the servo

- (0: full speed in a direction, 180: full speed in the other, and around 90: no movement)

- e.g., servo.write(angle), angle = 0 to 180

- detach() - stop an attached Servo from pulsing its I/O pin

http://arduino.cc/en/Reference/Servo

| C++ | Blocks |

|---|---|

#include <Servo.h>

Servo servo_7;

void setup()

{

servo_7.attach(7);

}

void loop()

{

servo_7.write(45);

// a variable can also be used instead of the constant (45)

delay(10);

}

/* servo connected to pin 7 will maintain an angle of 45 degree */

]] ></ac:plain-text-body></ac:structured-macro></div></td><td><div class="content-wrapper"><p><ac:image ac:thumbnail="true" ac:width="300"><ri:attachment ri:filename="image2020-1-20_17-58-31.png" /></ac:image></p></div></td></tr></tbody></table><p><br /></p><p><br /></p><p><br /></p><p><ac:image ac:height="250"><ri:attachment ri:filename="image2019-12-28_18-47-48.png" /></ac:image></p><p>Caution : Do not overload the servo. The servo and your battery / power source could be damaged if servo is overloaded.</p><p>Do not power the servo from a 9V battery. Most servos can’t take > 6V.</p><p><br /></p>

|